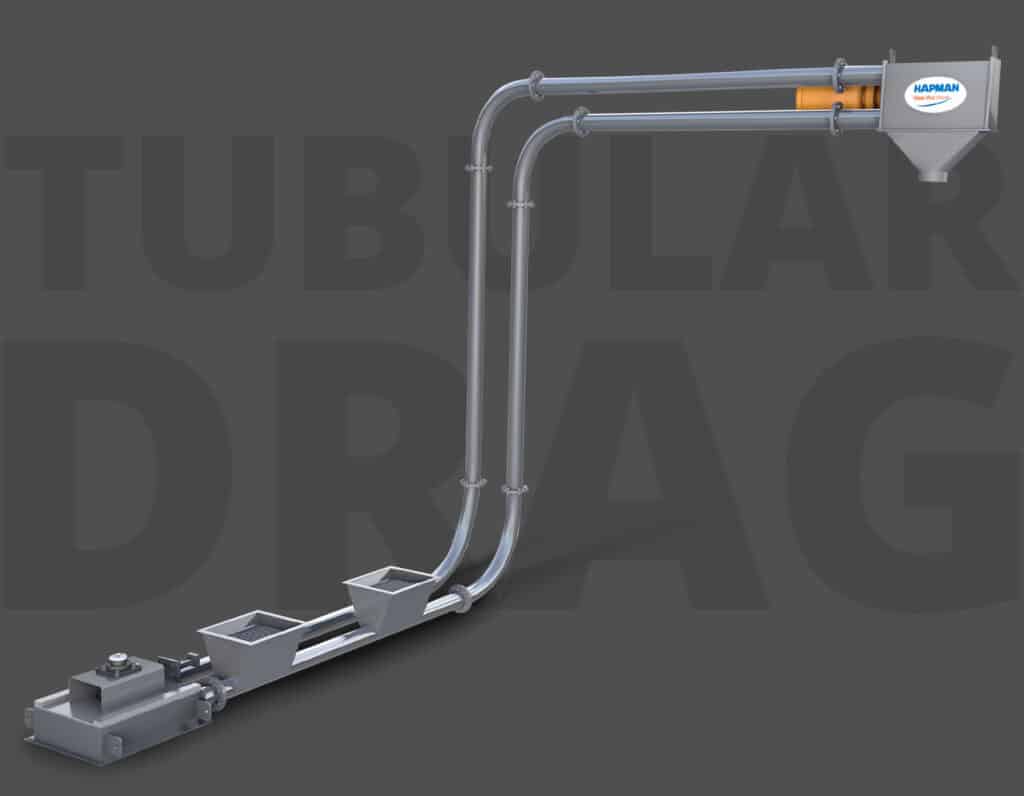

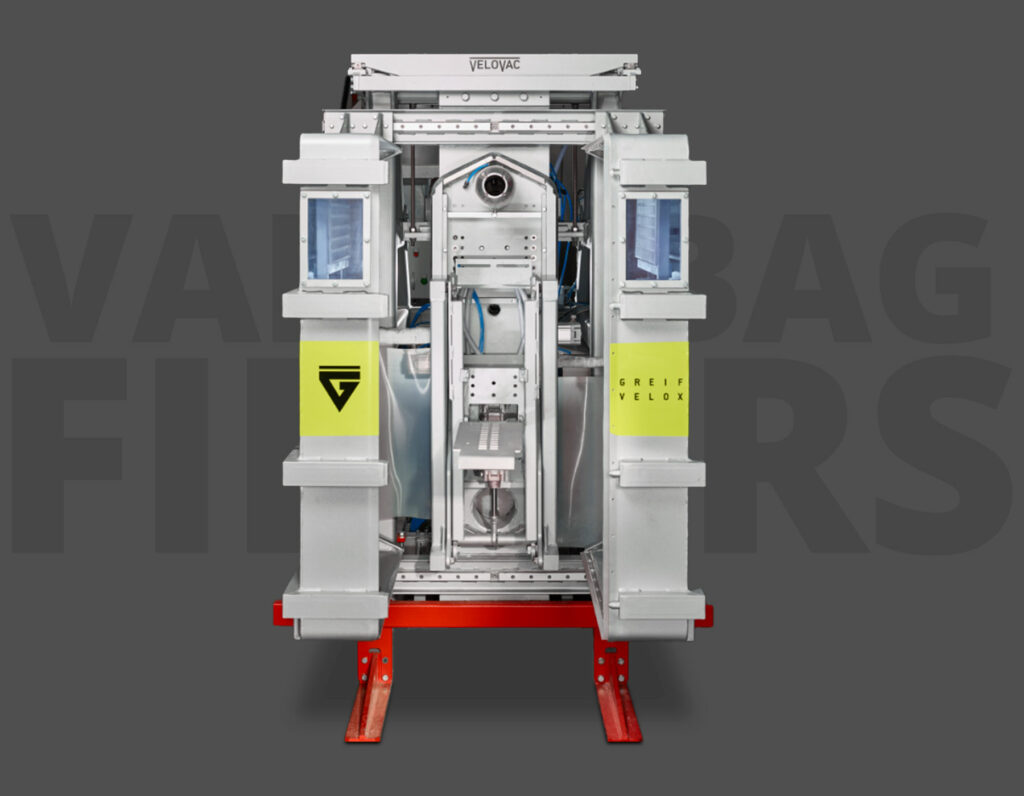

Trusted source to convey, handle, and process bulk materials

Hapman bulk material handling equipment keeps your process moving. Designed, built and supported in the U.S., Hapman equipment is designed for effortless operation, fast teardown for cleaning and maintenance and proven durability.